Maintenance

BEFORE USe - CHECK IT!

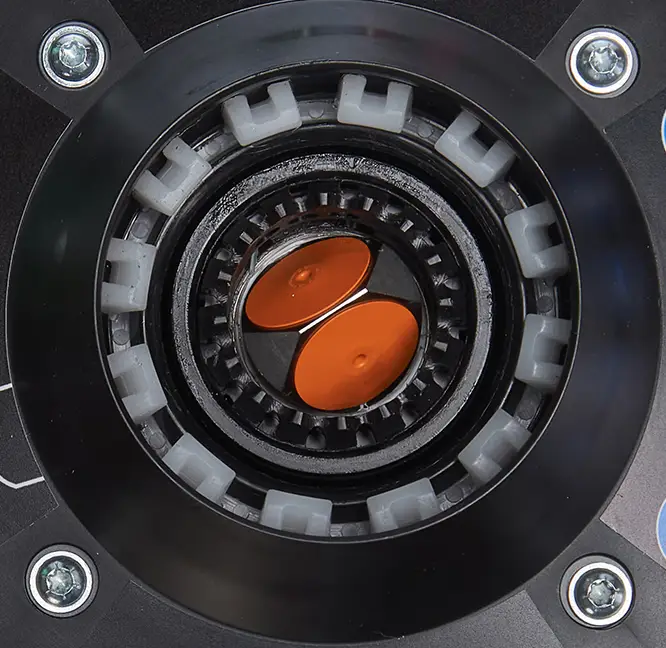

Make a visual check of Cleanload Nexus before use, lift the top cover and check the umbrella valves and white securing teeth.

Check that mounting is secure and the operating handle moves freely and all hose connections are tight.

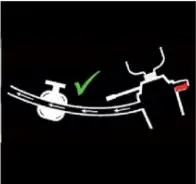

Only use containers with factory fitted easyconnect caps and check that suction is drawing from Cleanload Nexus before fitting a container.

Test with a container of water to check for leak-free transfer before using chemicals.